Preface: Time flies, and as we stand at the beginning of 2026, we pause to look back at the year that was 2025. This was a year in which technological innovation broke through at an unprecedented pace, while market demands continued to evolve in deeper, more specialized, and more stable directions. It was a year of coexisting opportunities and challenges, a dance of innovation and perseverance. Faced with a complex and ever-changing external environment, YINUOLINK chose a clear and determined path: not chasing fleeting trends, nor fearing short-term fluctuations, but instead settling our minds, focusing inward, and strengthening our foundations; looking towards substance to forge quality products; seeking synergy to empower scenarios; and moving forward with vision to collectively draw a blueprint for the future. We firmly believe that true opportunities always favor those who are down-to-earth and possess far-sighted vision.

Therefore, in 2025, we systematically optimized our R&D processes, consistently solidified quality control standards, and tangibly enhanced collaboration efficiency, steadily strengthening every link in the chain from product conception to final delivery. At the same time, we delved deep into application scenarios such as industrial automation, equipment interconnectivity, the low-altitude economy, and AI, ensuring that our technology genuinely addresses the real-world needs of our customers. Through solid progress, verifiable breakthroughs, and reliable delivery, we have presented an answer sheet centered on "professionalism, reliability, and long-term value" to all the clients, partners, and colleagues who have trusted and supported us. This record not only commemorates the hard work of the past year but also lays a sturdy foundation for our journey into the future.

Rooting Inwar: Building a Solid Foundation for High-Quality Development

We have always firmly believed that exceptional products are built through down-to-earth efforts, not by relying on fleeting moments of inspiration. Especially for a growing enterprise like ours, establishing a set of fundamental operational rules that can translate "good ideas" into stable, tangible outcomes and ensure consistent quality is far more critical than pursuing isolated technological breakthroughs. In 2025, all our internal optimizations centered on one clear bullseye: embedding the philosophy of "product supremacy and quality first" into every step of our daily work. We continuously refined our processes and solidly enhanced our capabilities, using our evolving operational standards to support the demands of the company's sustained development.

Standardized R&D Processes: Building a Clear and Traceable Path for Product Realization

In 2025, we undertook a focused and pragmatic optimization of our product development process, with the core objective of making every step from conception to market launch clearer and more controllable, ensuring that all critical stages can withstand rigorous scrutiny. This transformation was driven by our commitment to a higher standard of self-discipline: when faced with any potential issue, the team must adhere to the belief of "resolving it thoroughly in the first version," translating this conviction into tangible action by "using standards to validate problems and templates to solidify solutions."

In the past, project documents were often scattered across engineers' local computers or internal email accounts, leading to confusion as versions multiplied. To prevent knowledge fragmentation and avoid repeating past mistakes, we thoroughly optimized the "R&D Process and Management System" and strictly enforced the R&D design review mechanism. At critical junctures such as product structure, component selection, and software logic, we conduct multi-perspective evaluations, striving to identify and intercept potential risks at the drawing stage to ensure "getting the design right the first time." Any changes, whether in hardware or software, require the issuance of an Engineering Change Notification (ECN), which is formally communicated via email to all relevant departments. This process not only ensures that every adjustment is documented and information remains synchronized but also embeds a rigorous attitude of "verifying issues" into every decision, thereby systematically reducing the potential risks associated with changes.

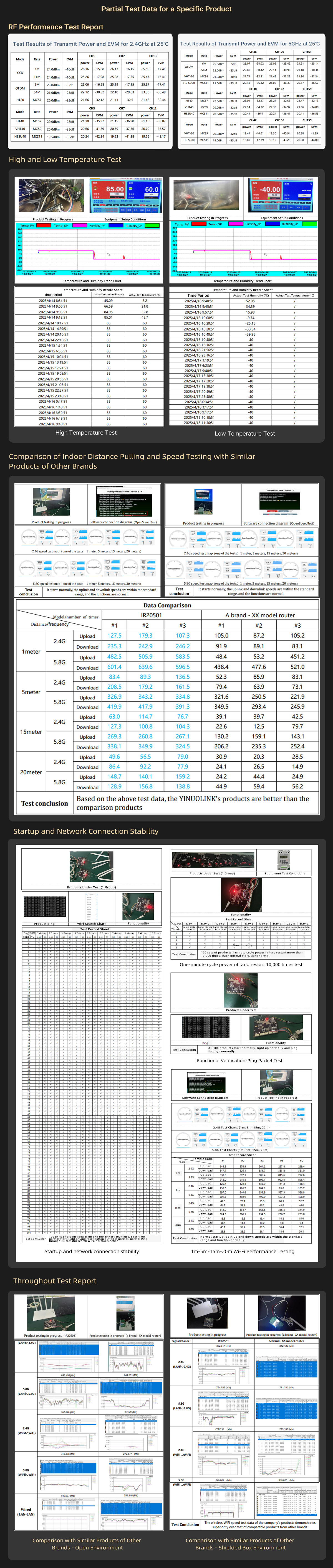

In the testing and verification phase, we systematically refined our testing procedures, establishing a multi-dimensional test matrix covering functionality, performance, compatibility, and critical reliability. Clear testing processes and standards were defined for different products. For instance, the "Wireless RF Test Report" and "Outdoor Distance and Traffic Testing" are conducted to verify signal stability in complex scenarios before mass production; the "High/Low Temperature Test Report" and "Waterproof Performance Testing" aim to confirm product durability in harsh environments; while the "One-Minute Cycle Startup Aging Test" validates long-term operational reliability. All test reports are uniformly archived, facilitating traceability and transforming the process and outcomes of "issue verification" into reproducible standard evidence.

More importantly, unified testing standards such as the Throughput Test and Comparative Testing Specification provide a consistent benchmark for quality, completely eliminating vague judgments like "I think it's fine." When issues arise, historical test records can be quickly traced to accurately pinpoint whether the cause is a design flaw, batch variation, or environmental factors, significantly shortening troubleshooting cycles and reducing redundant debates and internal inefficiencies. At the same time, all reports and supporting Operating Guidelines—such as those for WiFi test equipment and high-low temperature chambers—are centrally archived. This enables new team members to get up to speed quickly, ensures project handovers no longer rely on individual memory, and reduces project risks and quality fluctuations caused by personnel changes.

The fundamental purpose of process optimization is to ensure clear team goals and aligned actions. By implementing the BOM and ECN Change Process and the Software Change Execution Form, we ensure that any modifications are synchronized across all relevant stages, fundamentally preventing production errors, material stagnation, or version confusion caused by information misalignment. Refining and standardizing testing protocols is not about increasing workload but about making it clear to everyone "how much needs to be done and to what extent it is considered up to standard." This allows us to move past redundancy or omission and focus our energy on the design and optimization that truly create value.

We understand well that a perfect R&D management system cannot be built overnight. For a growing company like ours, the most critical step is first establishing clear "rules to follow" for our core processes. The most profound change this has brought about is the cultivation of a new work culture: addressing early uncertainties with a resolve to solve them, replacing subjective judgments with objective verification standards, and passing on successful practices through standardized templates. What we are building is not merely a set of complex procedures, but a supportive system that continuously accumulates experience, solidifies best practices, and steadily enhances product reliability. All of this will ultimately translate into more stable, more trustworthy products for our users—products that will support the company’s journey toward a sustainable future.

Production and Quality Control Process Optimization: Steadily Advancing Toward the Goal of a 0.05% Defect Rate

To tangibly enhance product stability and reliability, in 2025 we continued advancing a clear objective established as early as 2024 in the realm of production and quality control: maintaining a product defect rate below 0.05% before leaving the factory, and ensuring this requirement is embedded throughout the entire manufacturing process—not merely as a statistical figure.

The foundation of quality lies in establishing clear, measurable standards. For each product, we define explicit quality criteria that cover quantifiable metrics such as raw material specifications, component precision, and finished product performance and stability. Building on this, we translate standards into actionable steps by developing more detailed work instructions—the SOP (Standard Operating Procedure)—for the production line. These procedures clearly specify the operational steps, tools used, key parameters, and precautions for each process, ensuring that production activities are carried out with clear guidelines and reliable benchmarks.

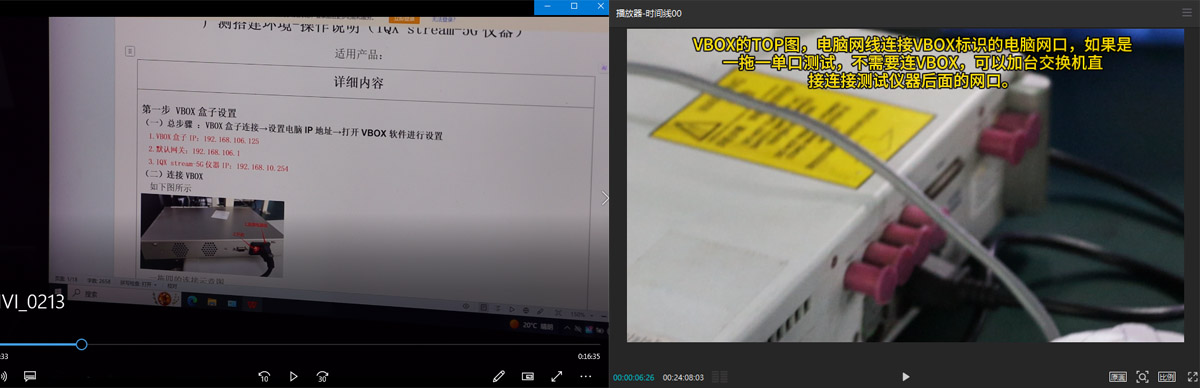

To ensure standards are truly implemented and operational variations are minimized, we have created detailed video operation guides for core production and testing equipment. For example, for high-low temperature chambers, we recorded full-process demonstrations covering startup, temperature curve setting, sample placement, and routine maintenance. For throughput testers, the videos clearly illustrate practical steps such as test script configuration, data reading, and troubleshooting. Additionally, key procedures like consumable replacement and calibration for label printers, as well as parameter settings and process validation for ultrasonic equipment, have all been standardized through video formats. This dual guidance approach of "illustrated manuals + video demonstrations" effectively standardizes operating methods across different personnel, reducing operational errors at the source.

At the critical juncture connecting R&D and production, we have taken concrete measures to ensure that the reliability established during the design phase is seamlessly transferred to the manufacturing end. The R&D team not only provides standardized documents such as the Production Test Setup Environment and VBOX Setup Instructions but also creates accompanying instructional videos to guarantee that the test environment is built and configured accurately and consistently. We have focused on optimizing the production testing process; for instance, through repeated "WiFi Calibration Balance Tests," we have steadily increased and maintained the initial calibration pass rate between 90% and 99%, tailored to different product batches, models, and quantities, significantly enhancing production efficiency and product consistency. In the programming stage, we strictly adhere to the FLASH Programming Pre - and Post-Verification Checklist for double-checking. Furthermore, prior to mass production, we rigorously follow the First Article Inspection Procedure, conducting comprehensive validation of the first article—from appearance and assembly to functionality and high/low-temperature reliability—to eliminate systemic risks at their root.

Materials are the foundation of quality. Our established Incoming Material Inspection Standard clearly defines inspection items, methods, and sampling plans for all critical components. All materials follow a unified coding system to ensure specifications, models, and other information are clearly traceable. In addition to routine visual and dimensional checks, key materials such as chips and modules are sampled and tested on actual equipment to verify that their performance and compatibility meet design expectations, intercepting potential issues early.

For SMT (Surface Mount Technology) processes, we assign dedicated personnel to monitor the production flow, provide real-time feedback on design or process issues, and conduct strict sampling inspections. Depending on the product batch, model, and quantity, the SMT first-pass yield remains stable between 95% and 99.5%.

During internal production, each workstation strictly follows SOPs and video guides. After every process step, inspection is carried out according to the Finished Product Inspection Standard, and only compliant items proceed to the next stage. Once products are assembled, every unit undergoes extended aging tests to ensure long-term stable operation. For industrial-grade products, samples are subjected to high-low temperature cycle tests ranging from -40°C to 85°C, simulating extreme conditions across different scenarios to identify potential flaws in advance and guarantee stable performance under all operating conditions.

The repair process adheres to the same rigorous principles: the root cause of any failure must be identified, and repaired products must pass the complete testing and aging procedure again before being returned to inventory.

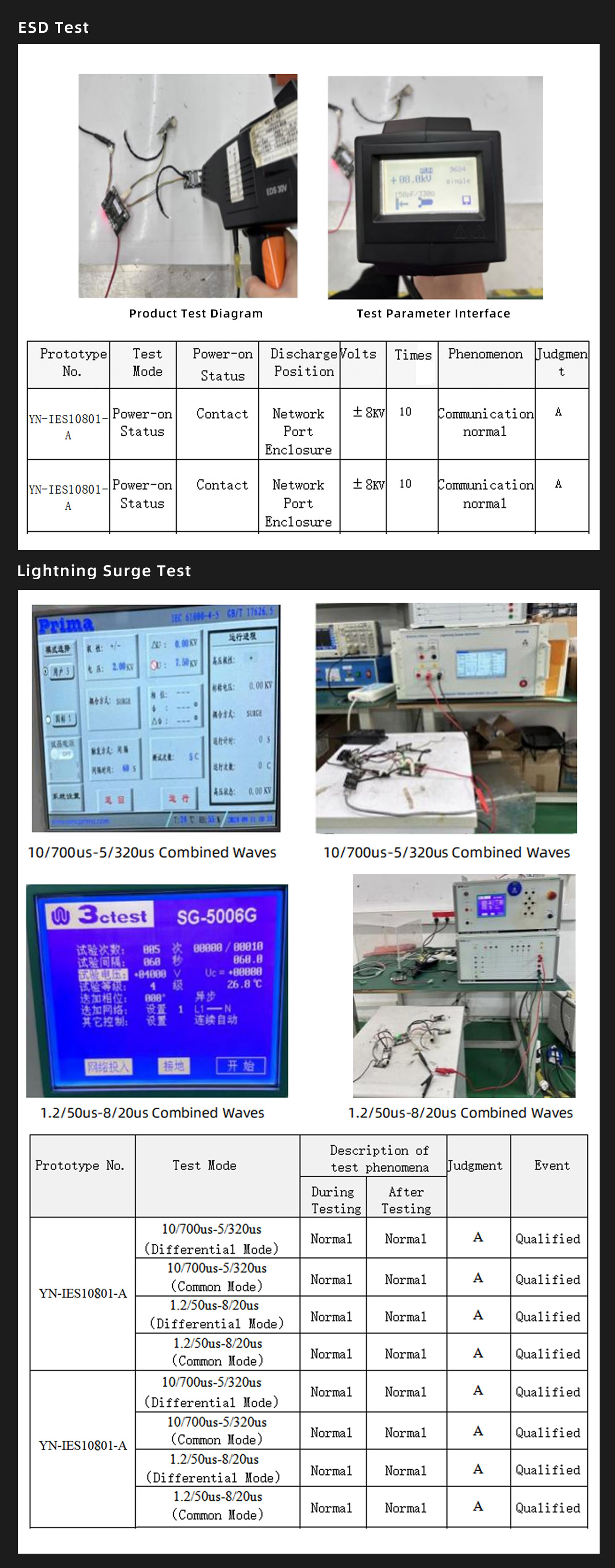

To enable rapid traceability of quality issues and drive continuous improvement, we have established a concise and practical end-to-end traceability mechanism. Since 2024, we have implemented categorical labels for production steps, assigned unique codes to each operator, and maintained real-time records of any issues arising during the manufacturing process. Once feedback is received from the market, we can swiftly trace back through the entire production history of the product, accurately pinpoint the root cause of the problem, and promptly develop and implement corrective actions to prevent the recurrence of similar issues. Furthermore, regarding electrostatic discharge (ESD) protection, building upon the specialized training conducted in 2024, we further refined the on-site alert system in 2025, deeply integrating ESD awareness into every detail of daily operations to strengthen the final line of defense for quality protection.

All these efforts serve one clear purpose: by establishing actionable standards, providing visual guidance including videos, and controlling every critical checkpoint, we make daily operations clearer, more consistent, and more manageable. This systematically reduces errors and solidly enhances the inherent stability of our products. We firmly believe that only by executing every concrete task in R&D, material management, outsourced production, and internal control with thoroughness can the quality goal of 0.05% defect rate be transformed from a concept into tangible reality.

Supply Chain and Procurement Management Optimization: Building a Resilient, Transparent, and Collaborative Supply Network

We are keenly aware that we cannot control the macro-environment, but we can enhance our resilience to external changes by optimizing our management models and collaboration mechanisms.

With years of deep expertise in the network communications industry, we have always believed that the foundation of high-quality products lies in rigorous supply chain control. As a manufacturer with independent research, development, and production capabilities, the procurement department is not only a hub for material flow but also a core unit for selecting premium partners and safeguarding product quality. From the strict qualification of new suppliers to the long-term management of existing ones, every step of the process embodies our operational philosophy of "Quality First, Integrity and Mutual Benefit," injecting enduring momentum into the steady growth of the enterprise.

In the supplier qualification process, we adhere to a principle of "strictness first." The procurement department begins by conducting compliance checks on the supplier's business license, production certifications, and other fundamental documents. This is followed by a preliminary screening through procedures such as sample submission, quotation comparison, and sample sealing and approval. Subsequently, a multi-departmental joint review is conducted, covering documents like the "Supplier Survey Form," the signing of the "Quality Agreement," and the "Green Environmental Commitment." Only after being entered into the qualified supplier system does formal collaboration commence. Upon delivery of materials, the incoming inspection department rigorously evaluates each batch. Qualified items are accepted into inventory, while non-conforming items trigger immediate exception handling procedures. This standardized process ensures that every batch of materials meets production requirements and establishes the initial line of defense for the supply chain.

If qualifying new suppliers is a cautious process of "selecting one from a hundred," then maintaining relationships with existing suppliers is a "deep cultivation" of long-term value. In our view, long-standing suppliers are invaluable assets to the company's development. They are familiar with our product requirements, have a high degree of synergy with our processes, and demonstrate strong cooperation, with their stability directly impacting production efficiency and the consistency of product quality. When material issues arise, we move beyond a simple "blame and rectify" approach. Instead, we collaborate closely with our established suppliers to conduct root cause analysis, examining everything from raw materials and production processes to packaging and logistics, jointly developing corrective action plans. This approach transforms problems into opportunities for optimization and upgrades, strengthening our partnership through the very process of resolving challenges.

Dynamic feedback in the incoming inspection process is an even more critical link in maintaining long-term suppliers. For materials delivered by established suppliers, the incoming inspection department still upholds a zero-tolerance quality bottom line. If non-conforming products are identified, in addition to issuing a Quality Abnormality Notification Letter in accordance with procedures, the procurement department will immediately communicate with the supplier to identify root causes, assisting them in pinpointing issues in production processes, raw material control, and other areas to prevent the recurrence of similar abnormalities.

At the same time, incoming inspection data for each batch is compiled and archived to form a long-term supplier quality database, providing data support for subsequent evaluations and partnership adjustments.

Furthermore, we steadfastly uphold the principle of "integrity in cooperation and mutual benefit through honesty," fostering a fair and transparent environment for our established suppliers. We strictly prohibit any form of unethical benefits, and instead, build trust and respect through sincere communication and impartial treatment, allowing our partnerships to thrive on a foundation of pure value alignment.

From the stringent qualification of new suppliers to the meticulous stewardship of long-term partners, our supply chain management consistently revolves around two core principles: "quality" and "mutual success." In today's rapidly evolving networking and communications industry, we will continue to advance alongside all our partners with professional processes and an open mindset. By linking ingenuity and fostering shared success, we are committed to delivering superior products and services to the market, collectively writing a new chapter in the industry's development.

This year, we may not have had dazzling external moves, but we firmly believe that these internal efforts to “cultivate our core strengths”—standardizing R&D processes, refining quality control, and streamlining supply chain collaboration—while unassuming, are the fundamental guarantee that enables us to consistently deliver stable and reliable products to the market and go further in the long run.

Born for Stability, Strengthened by Connection — Panoramic Connectivity Solutions Empower Growth

As the industrial internet and smart manufacturing advance, the role of network connectivity has undergone a fundamental transformation. It has evolved from a supportive "information transmission channel" in the past to a "critical link" underpinning production operations and a "core artery" carrying data value. The stability and reliability of networks directly impact the smoothness of production processes, operational efficiency, and the speed of decision-making responses.

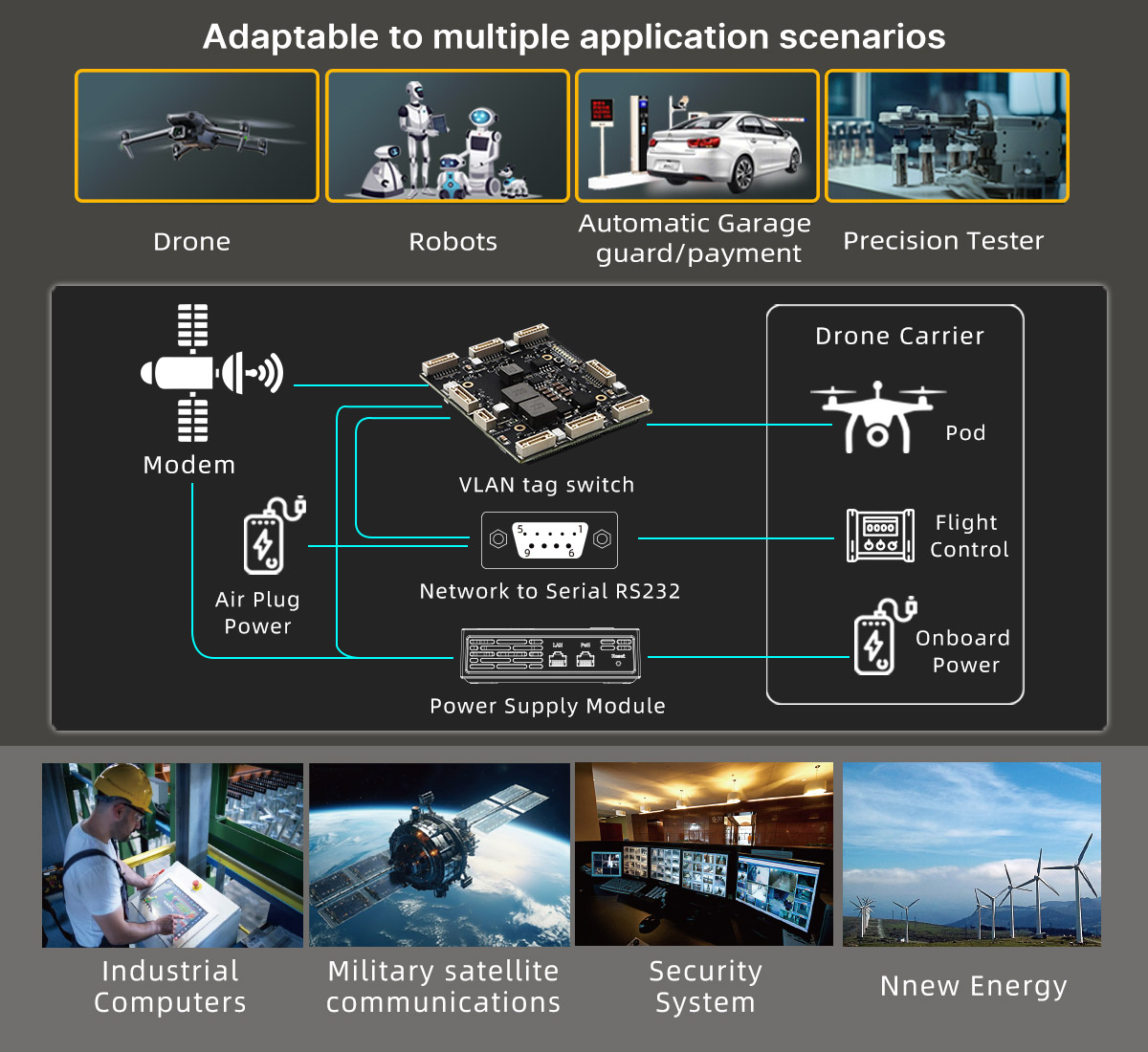

YINUO-LINK deeply grasps the direction of the modern industrial system emphasized in the "15th Five-Year Plan" and actively aligns with strategic emerging industries such as the low-altitude economy, artificial intelligence, robotics, and new energy. We continuously expand the depth and breadth of connectivity technology applications. Our understanding of "industrial-grade" has never been confined to traditional industrial scenarios. Instead, we focus on the solid capability to ensure connectivity remains "continuously online, stable, and reliable" in complex, harsh, or highly dynamic real-world environments. We are committed to extending rigorously validated industrial-grade reliability and adaptability to more emerging fields. Through flexible product and solution combinations tailored to diverse scenario needs, we provide a dependable connectivity foundation for the digital and intelligent transformation of industries across the board.

Industrial-Grade Connection Stability: Multi-Dimensional Protection, Unfazed by Environmental Challenges

We understand the complexity of industrial field environments, so we prioritize environmental adaptability from the product design stage and implement targeted protection designs in critical links:

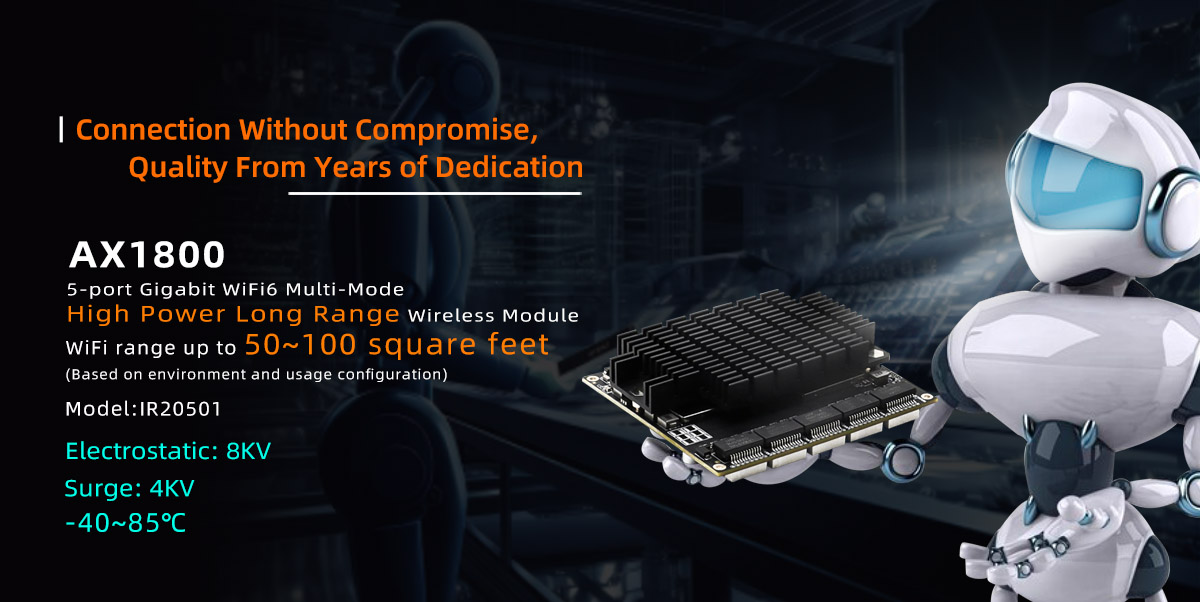

ESD Protection: All external ports are designed with professional-grade protection, ensuring they can withstand contact discharge of 8KV and air discharge of 15KV. This effectively prevents both latent and overt damage to the device’s internal precision integrated circuits caused by static electricity from human bodies or tools during installation and maintenance, guaranteeing long-term stable operation of the equipment.

Surge & Lightning Protection: Built-in high-efficiency professional protection circuits effectively defend against induced lightning surges and power line fluctuations ranging from 1KV to 8KV (protection level varies by product). This ensures that when deployed in complex grid environments and lightning-prone areas (such as fields, mining areas, and building tops), the equipment’s data paths and power systems remain rock-solid, safeguarding the absolute security and integrity of critical data.

Wide Voltage Adaptive: Supports a wide DC input voltage range of 9V to 36V and even wider, with excellent voltage ripple suppression capability. This design fundamentally resolves voltage fluctuations and drops caused by long power supply lines and frequent load start/stop in industrial fields, preventing frequent restarts, abnormal operation, or permanent damage to equipment due to unstable voltage, and greatly improving the overall reliability of multi-device systems.

Extreme Temperature Resistance & Wide-Temperature Operation: Rigorously selected industrial-grade long-life components, combined with optimized thermal design and reliability verification, ensure the entire line of industrial-grade products operates stably for long periods in extreme environments from -40°C frigid cold to 85°C high heat. Whether in the icy cold of northern outdoors, the sweltering humidity of southern workshops, or specialized high/low-temperature scenarios such as cold-chain logistics, metallurgical kilns, and photovoltaic power stations, YINUOLINK connectivity equipment keeps the network “always online.”

Human-Centric Design: Enhancing Deployment Efficiency and Operational Reliability Through Usability

We firmly believe that true stability and reliability should not come at the cost of complex deployment and difficult maintenance. Therefore, we always design from the practical operation perspective of field engineers, system integrators, and end users, deeply integrating the philosophy of "easy deployment, easy maintenance, and high compatibility" into every detail of product design.

Error-Proof & Protection Design: Equipped with comprehensive reverse polarity protection for power input, which fundamentally eliminates instantaneous equipment damage caused by incorrect wiring operations, significantly lowering the threshold and potential costs of installation and commissioning.

Compact & High-Integration Design: Leveraging advanced miniaturized packaging and high-density circuit design, our powerful communication modules can be easily embedded into various industrial smart devices with extremely limited internal space—such as the dexterous joint controllers of industrial robots, compact flight control systems of UAVs, built-in communication units of mobile medical equipment, and diverse industrial intelligent sensor terminals—helping equipment manufacturers build more competitive integrated products.

Unite to Empower: A Panoramic Solution Driven by Dual Engines of Wireless & Wired Connectivity

Our WiFi product portfolio adheres to the strategy of parallel development and mutual complementarity of wireless and wired technologies, aiming to provide complete and flexible connectivity support for the digital, networked, and intelligent transformation of various industries.

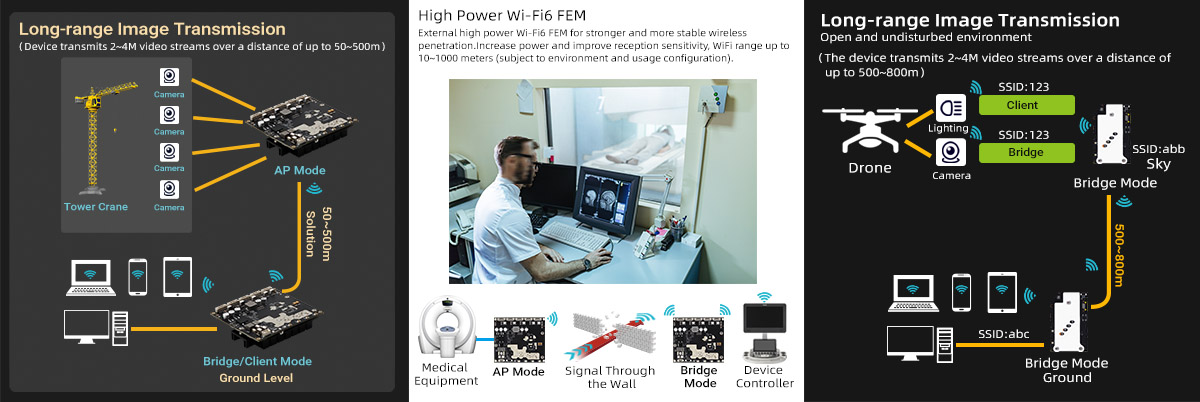

Full-Rate and Full-Scenario Wireless Capability Matrix: We provide a comprehensive range of solutions, from cost-effective megabit-level WiFi modules that meet the demands of smart homes and basic IoT data collection, to high-performance gigabit-level WiFi modules (such as our Wi-Fi 6 technology-based series) that support HD video surveillance and large-file wireless transfers, all the way to outdoor high-power enhanced wireless APs and routers specifically designed for long-distance, wide-coverage, and complex environments. With varying speeds and transmission powers, our products are precisely tailored to diverse scenarios—from high-density indoor device connectivity and high-speed enterprise wireless offices to outdoor point-to-point bridging over several kilometers.

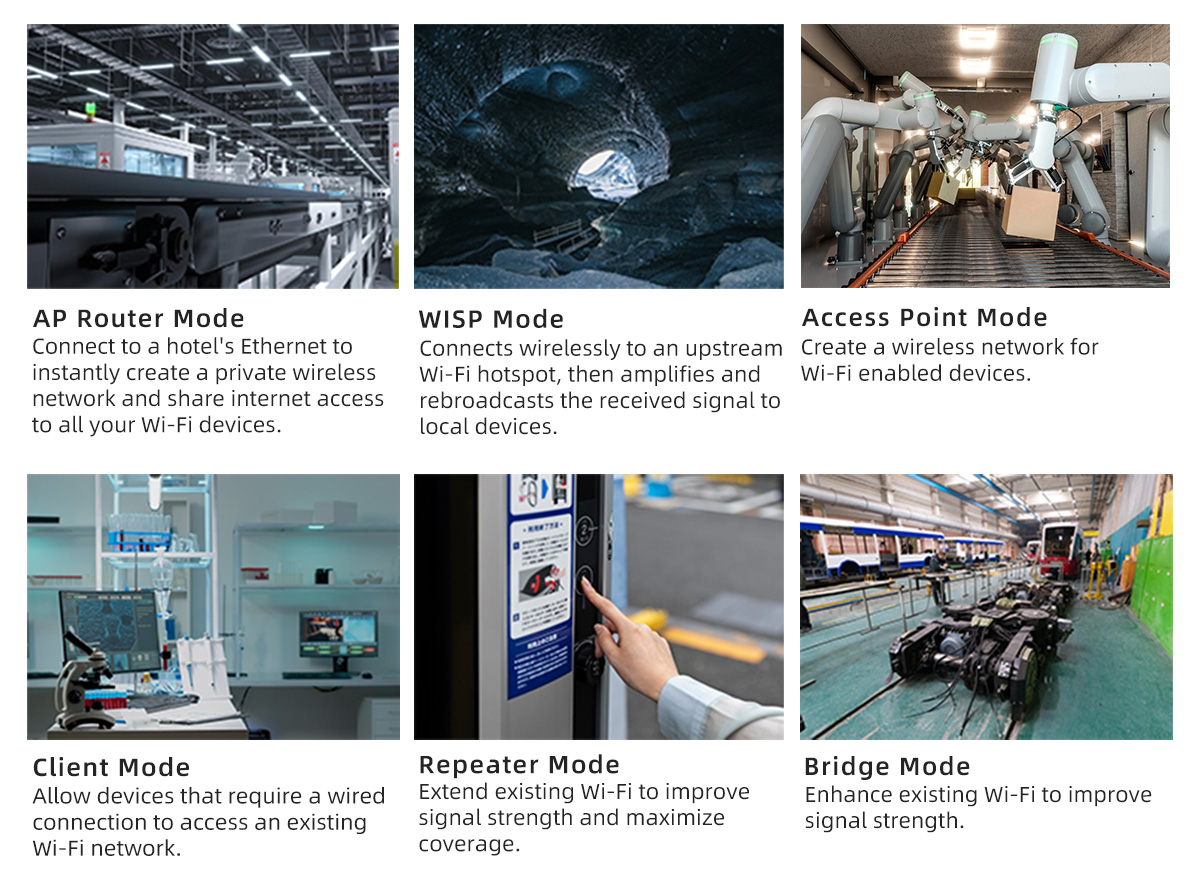

Multi-Mode Flexible Networking: Supports six working modes, including Wireless Access Point, Wireless Router, Wireless Client, Wireless Repeater, Wireless Bridge, and WISP Client. This means that whether you need to build a new wireless network, access an existing network, or perform long-distance point-to-point bridging, a single device can flexibly switch roles, greatly simplifying the complexity of network planning and deployment.

Empowering Core Industrial Scenarios

Smart Manufacturing and Industrial Robots: Our high-performance Gigabit WiFi modules provide industrial robots with stable and low-latency wireless connections, enabling real-time transmission of high-definition visual data, precise collaborative motion control, and synchronized production status updates. They serve as the core wireless link for flexible production lines and intelligent logistics warehouses.

Drones and Aerial IoT: Provides beyond-visual-range, anti-interference video transmission data links and flight control signal assurance for various industrial drone platforms. Widely used in fields such as surveying and mapping, inspection, security, and agricultural plant protection, extending connectivity from the ground to the sky.

Smart Cities & Public Safety: Our high-power wireless APs and routing products deliver stable, reliable wireless coverage for video surveillance, information dissemination, and device interconnection in smart parks, digital ports, and large-scale stations. They solve connectivity challenges in areas where wired deployment is difficult.

Smart Energy & Transportation: In highly reliability-demanding scenarios such as substations, photovoltaic power stations, oil and gas pipeline monitoring, and rail transit, our industrial wireless devices shoulder the critical tasks of data acquisition and monitoring signal transmission. Their wide-temperature resistance, surge protection, and high-stability characteristics make them perfectly suited for the harsh and complex outdoor operating environments.

Switching Panoramic Matrix: Autonomous & Controllable, Building a Solid Network Foundation

Actively responding to the national strategic call for the application and innovation of information technology and industrial autonomy, we have continuously invested in the enterprise-level and industrial-grade Ethernet switch field, achieving leaping development from technology following to independent innovation, and from single product supply to full-scenario solution provision.

We have completed the localized layout of core modules and products for the entire series of switches, and closely focused on the real needs of industrial and enterprise networks, building a complete, reliable, secure, and autonomous controllable product matrix.

Independent Core, Secure and Trustworthy: The entire range of switch products adopts domestically leading autonomous and controllable switching chips and embedded system solutions. From the core hardware and basic software levels, it ensures the supply chain security, technical security, and data communication security of critical information infrastructure, meeting the strict requirements for autonomy and controllability in specific industries.

Full-Scenario In-Depth Coverage

Embedded Compact Series: Featuring a small, miniaturized form factor (e.g., pin header interface for direct soldering onto the customer's boards), this series is designed for space-constrained applications such as drones, robotics, industrial control equipment, and built-in network devices to deliver plug-and-play switching functionality.

High-Density, High-Stability Series: Offers a variety of industrial-grade switches with specifications ranging from 2-port, 3-port, 4-port, 5-port, 8-port, 12-port, 24-port, to 26-port configurations. These switches meet the demanding requirements for port count, forwarding performance, and long-term operational stability in factory workshop production lines and data center aggregation nodes.

Intrinsically Safe Explosion-Proof Specialized Series: Designed in strict compliance with national mining intrinsic safety standards, this series is suitable for flammable and explosive hazardous environments such as coal mine underground operations, petrochemical plants, and gas stations, ensuring safe production.

PoE Power-Enabled Series: Fully compliant with IEEE 802.3af/at standards, this series enables simultaneous data transmission and power supply over Ethernet cables to connected devices such as wireless access points, network cameras, and IoT terminals. It significantly simplifies deployment in scenarios such as security surveillance, smart buildings, and wireless coverage.

Easy Smart Series: Building upon plug-and-play functionality, this series offers convenient management via a web interface. It supports practical management features such as VLAN segmentation, QoS, port isolation, port aggregation, port mirroring, and loop protection. This helps small to medium-sized industrial networks build smarter, more efficient, and more secure communication environments.

Connect the World, Service as Our Foundation — Building a Synergistic and Integrated Omnichannel Marketing and Service System.

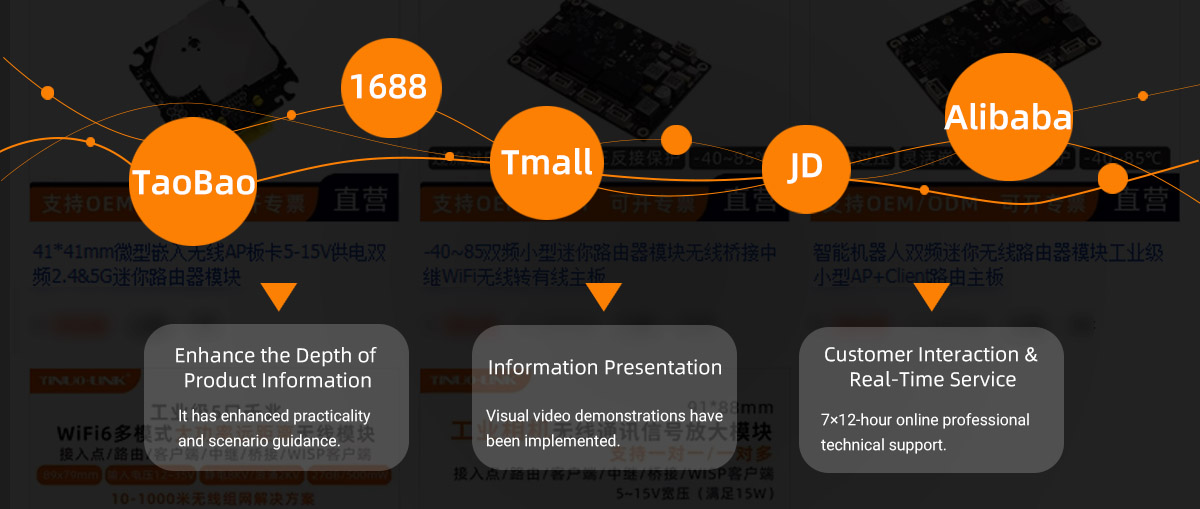

In 2025, while optimizing our internal management processes, we also comprehensively upgraded our market-facing customer engagement and service models. We expanded our presence by launching official flagship stores on Tmall and JD,and carried out a full-scale optimization and upgrade of our existing Taobao, Alibaba , and 1688 store—covering everything from visual identity and product display to content details. This has initially established an omnichannel marketing and service network that covers both domestic and international markets, integrates online e-commerce with offline channels, and enables collaborative synergy.

We position our e-commerce platforms as "a multidimensional window for product and technology demonstration, an entry point for real-time online technical support, and an active community for user and partner interaction." Through these platforms, we have directly gathered a vast amount of genuine feedback from end-users. This valuable firsthand information not only validates the value of our products in professional fields but also makes us clearly aware of a challenge: the existing products have a relatively high professional threshold, which creates barriers to understanding and usage when targeting a broader range of general consumers. To address this, we have systematically driven a series of improvements across three dimensions: the depth of product information, presentation formats, and real-time support.

To enhance the depth and transparency of product information, we have comprehensively upgraded the accompanying specification sheets and technical documentation. While ensuring parameter accuracy, we have placed particular emphasis on improving their practicality and scenario guidance. The specification sheets now systematically list physical and mechanical characteristics such as dimensions, mounting hole sizes, hole spacing, upper and lower height limits of the PCBA board, and finished product weight. Additionally, application scenario descriptions have been added to clearly explain the typical environments suitable for the product. Meanwhile, interface definitions and electrical characteristics have been further detailed to ensure accurate connection configurations.

Furthermore, for the first time, we have centrally displayed multiple key test data on the product detail pages. This includes test results for high-low temperature testing, one-minute cycle startup aging, throughput performance, wireless radio frequency, outdoor distance throughput testing, and more. Combined with information on core components, this provides solid data support for product quality, allowing customers not only to understand the specifications but also to perceive the reliability and durability of the products. Clear application scenario diagrams have also been added to the detail pages, visually demonstrating the deployment and connection methods of the products.

Regarding information presentation, we actively promote visual guidance. To address challenges in product understanding and operation, we have produced panoramic product showcase videos and step-by-step instructional videos. These convert complex textual explanations into easily understandable dynamic demonstrations, significantly lowering the learning curve and practical operational barriers for users.

In terms of customer interaction and immediate service, we are staffed with professional technical support personnel who provide 7×12-hour real-time online consultation, with an average response time controlled within 3 minutes. Whether it's product selection and comparison, compatibility confirmation before deployment, or configuration issues encountered during use, customers can receive prompt responses through our e-commerce platform. Technical support personnel can readily access product specification sheets, key test data, partial 3D drawings, comprehensive 2D drawings, and video libraries to provide precise guidance. They also offer remote assistance when necessary, transforming detailed yet static product information into timely and dynamic solutions. This truly achieves the goal of "ensuring peace of mind before purchase and hassle-free after-sales support."

Through these concrete and coherent improvements, we have not only built professional trust with solid technical data and authentic test performance but also paved a clear path of understanding and a smooth communication loop through scenario-based graphics, videos, and real-time technical support. This has extended our online channels from mere transactional touchpoints into a long-term window for serving customers and delivering value.

Forward and Beyond — 2026 Strategic Outlook: Scaling New Heights, Collaborating for Shared Success

In 2025, we made mistakes, experienced setbacks, and faced countless compromises and trade-offs. Yet each time, we chose to confront reality rather than avoid it. Building on the solid institutional foundation laid in 2025 and the extensive practical experience gained across numerous industry scenarios, we look toward 2026 and beyond with unwavering confidence and a clear vision. Our goal is not only to become an outstanding provider of communication equipment but also to gain a deeper understanding of the unique needs across different industries. Together with our partners, we aim to contribute our professional expertise toward solving specific challenges in real-world scenarios.

Continuous Optimization, Delivering on Quality Commitments: We will further advance our quality goal of maintaining a "0.05% defect rate," which demands greater attention to every detail in our production processes. In terms of supply chain management, we will focus on enhancing collaborative efficiency and information transparency with key partners, optimizing the forecast-to-delivery process, and striving to provide customers with more stable and timely product supply assurance.

Strategically Advancing into High-End Product Domains and Technological Frontiers

Moving toward the high-end innovation of the industrial value chain remains our unwavering strategic direction. In 2026, we will focus on the following key areas:

Customer Demand-Driven, Delivering Differentiated Value: We always take customer needs as the starting point for innovation and service, and are committed to providing differentiated value that goes beyond standard products. For us, ascending the value chain is fundamentally about extending from "supplying standard products" to "responding to deep-seated demands." We do not forcefully promote concepts or engage in empty talk about platforms. Instead, we insist on diving deep into our customers' operational sites, engaging in continuous and pragmatic dialogues to truly understand their real pain points in specific scenarios—whether it's the stringent demand for ultra-low latency in robotic production lines or the challenge of ensuring stable operation in harsh environments such as energy and low-altitude applications. These in-depth conversations are the foundation of all our services and innovations.

Building on our long-term expertise in professional connectivity, we can offer flexible and cost-effective customized support in hardware design, software functionality, and solution adaptation to meet customers' unique needs, ensuring that technology genuinely serves business scenarios and helps customers solve real problems and achieve tangible results.

To truly implement this model of "staying close to needs and responding swiftly," we solemnly launch the "Co-Creation Initiative": If you have innovative connectivity ideas or unique scenario requirements in your business, we welcome the opportunity to explore them with you. After a rapid internal assessment, we will actively collaborate with you to outline a feasible implementation path. For ideas with industry representativeness or forward-looking value, we are open to cooperative models, including free targeted development, to jointly transform concepts into actionable and verifiable solutions.

We look forward to engaging in a sincere and in-depth dialogue with you. Feel free to reach out to us via email at sales@yinuo-link.com for technical discussions. Let’s start with communication, solve specific problems together, and create tangible value collaboratively.

Leading the Wireless Technology Revolution, Embracing WiFi 7: We are actively developing cutting-edge products based on the IEEE 802.11be (WiFi 7) standard. With features such as Multi-Link Operation (MLO), wider channels, and higher-order modulation, WiFi 7 delivers multi-fold increases in throughput, deterministic ultra-low latency, and enhanced network efficiency. This will enable revolutionary experiences in scenarios such as 8K/VR/AR applications, fully wireless factories, and high-end office environments.

Accelerating Wired Network Backbones, Deploying 2.5G and 10G Solutions: We are comprehensively launching a series of 2.5Gbps access-layer products to meet the growing demand for gigabit broadband in enterprises, high-definition video conferencing, and high-speed large file transfers. Simultaneously, we are deploying core aggregation switch series with 10Gbps and higher speeds, providing ample bandwidth for data centers, campus backbones, and cloud computing access. This initiative lays a robust network foundation to address application needs for the next 5–10 years.

Building an Open, Collaborative, and Win-Win Industrial Ecosystem: We firmly believe that "he who walks alone walks fast, but he who walks with others walks far." With a more open mindset, we will join hands with industry partners and system integrators to collaboratively build a dynamic "YINUO-LINK +" ecosystem. Our goal is to better empower our partners and work together to create more competitive integrated solutions for our customers.

Every solid step taken in 2025 reaffirms our inner conviction: in the grand narrative of the times, only by steadfastly pursuing product excellence, honoring our enduring commitment to customers, and relentlessly investing in innovation can we earn lasting respect and achieve sustainable growth. We consistently uphold the principle of "seeking truth from facts and staying grounded" in product development, firmly believing in the law of conservation of energy—every ounce of dedication poured into quality will ultimately transform into product reliability and user trust.

Here, we sincerely thank every customer for your choice and trust. It is your rigorous demands in practical applications that continually drive our progress. We extend our gratitude to every partner for your collaboration and companionship—it is your professionalism and dedication that collectively amplify the value of connectivity. We also thank every YINUO-LINK colleague for your hard work and dedication. It is your efforts, drop by drop, that have laid the foundation for the company today.

In 2026, YINUO-LINK Times will remain steadfast to our original aspiration of "Intelligent Connectivity, Sustained Stability," striving to deliver more reliable products, more scenario-aligned solutions, and engaging in cooperation with an even more open attitude. We look forward to standing alongside you, embracing every challenge and opportunity of the intelligent era.